The Inventory Management Statements

Wiki Article

The Single Strategy To Use For Inventory Management

Table of ContentsIndicators on Inventory Management You Should KnowThe Ultimate Guide To Inventory ManagementSome Ideas on Inventory Management You Need To Know8 Easy Facts About Inventory Management Shown

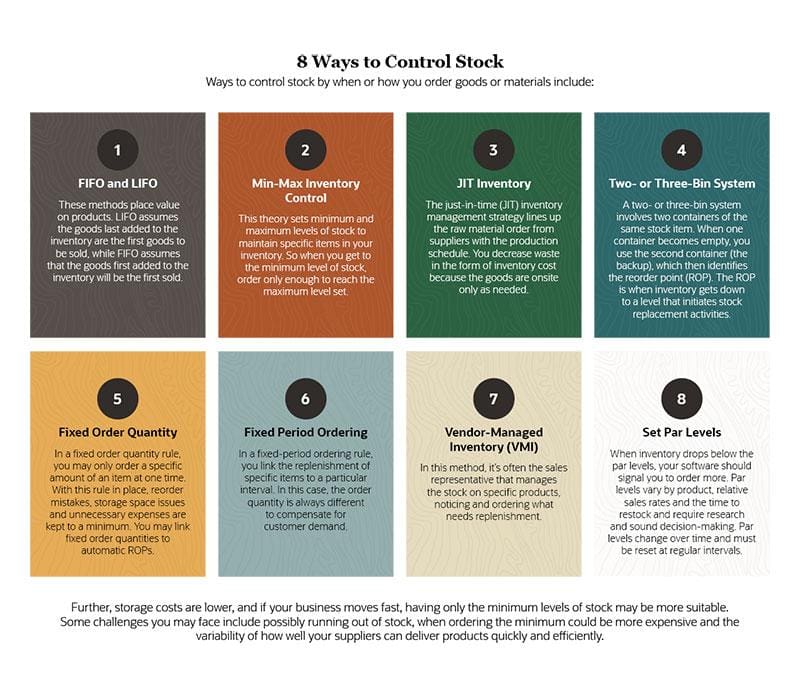

There are 2 main methods of maintaining track of supply: routine and also continuous. The major difference between these is how typically information is upgraded. No matter of exactly how often you track inventory, you might intend to utilize among the adhering to supply administration methods: ABC Analysis, ABC (Always Better Control) Evaluation is stock management that separates different things into three groups based on prices and also is divided into teams A, B, or C.The items in the B group are reasonably cheaper contrasted to the A group. And also the C category has the least expensive products of all 3. EOQ Design, Economic Order Amount is a method utilized for planning as well as purchasing an order amount. It involves deciding regarding the amount of stock that should be placed in supply at any kind of offered time. Inventory Management.

FSN Technique, This approach of stock control describes the procedure of keeping track of all the products of stock that are not made use of frequently or are not required constantly. They are after that categorized into 3 various classifications: fast-moving stock, slow-moving stock, and non-moving supply. JIT Approach, In the nick of time inventory control is a procedure used by makers to control their stock degrees.

The Inventory Management PDFs

VED Evaluation, VED is a strategy utilized by organizations to manage their stock. The high level of supply that is required for manufacturing usually validates the reduced inventory for those parts.Wrike is a task management solution that can help you do exactly that. With Wrike's product management tools, you can handle every one of your product team's activities in one location as well as obtain one of the most out of every task. Wrike's item launch automation assists speed up product launches with a structured strategy.

All About Inventory Management

Inventory management describes the process of buying, saving, utilizing, and also marketing a company's supply. This includes the monitoring of raw products, elements, and completed products, along with warehousing and also handling of such products. There are various sorts of inventory administration, each with its benefits and drawbacks, depending upon a firm's requirements.Stock administration tries to efficiently simplify supplies to stay clear of both excess and shortages. Four major supply monitoring methods consist of just-in-time monitoring (JIT), materials demand planning (MRP), financial order quantity (EOQ), as well as days sales of inventory (DSI). There are advantages and disadvantages per of the methods, examined listed below. A firm's inventory is just one of its most important possessions.

A lack of stock when and where it's required can be incredibly detrimental (Inventory Management). At the same time, supply can be thought of as a liability (if not in an audit feeling). A huge stock brings the threat of putridity, theft, damage, or changes popular. Inventory needs to be guaranteed, as well as if it is not offered in time it may have to be thrown away at clearance pricesor just damaged.

Recognizing when to replenish supply, what total up to buy or generate, what price to payas well as when to sell and also at what pricecan quickly ended up being complicated decisions. Small companies will certainly typically monitor stock manually as well as figure out the reorder points as well as quantities utilizing spread sheet (Excel) formulas. Bigger organizations will certainly utilize specialized venture resource planning (ERP) software program.

The Basic Principles Of Inventory Management

Suitable stock monitoring approaches vary depending on the sector. An oil depot is here are the findings able to store large quantities of inventory for extensive time periods, permitting it to wait on need to choose up. While saving oil is pricey and riskya fire in the U.K. in 2005 brought about millions of pounds in damages and also finesthere is no threat that the supply will ruin or go out of style.For firms with complicated supply chains as well as manufacturing processes, balancing the threats of supply excess as well as scarcities is particularly hard. To accomplish these balances, firms have developed a number of approaches for inventory management, including just-in-time (JIT) and products demand preparation (MRP). Some firms, such as financial services companies, do not have physical inventory therefore must rely upon solution process management.

Inventory has to be physically counted or determined prior to it can be placed on an annual report. Firms typically keep innovative supply monitoring systems qualified of tracking real-time stock levels. Inventory is accounted for using one of 3 browse this site techniques: first-in-first-out (FIFO) setting you back; last-in-first-out (LIFO) setting you back; or weighted-average costing. An inventory account usually includes 4 separate groups: Basic material stand for different products a business acquisitions for its production process.

Operate in procedure (additionally known as goods-in-process) stands for basic materials in the process of being changed into an ended up product. Finished items are completed products easily offered available to a firm's consumers. Product represents finished goods a firm purchases from a distributor for future resale. Depending on the type of service or item being examined, a firm will certainly utilize numerous supply administration methods.

Report this wiki page